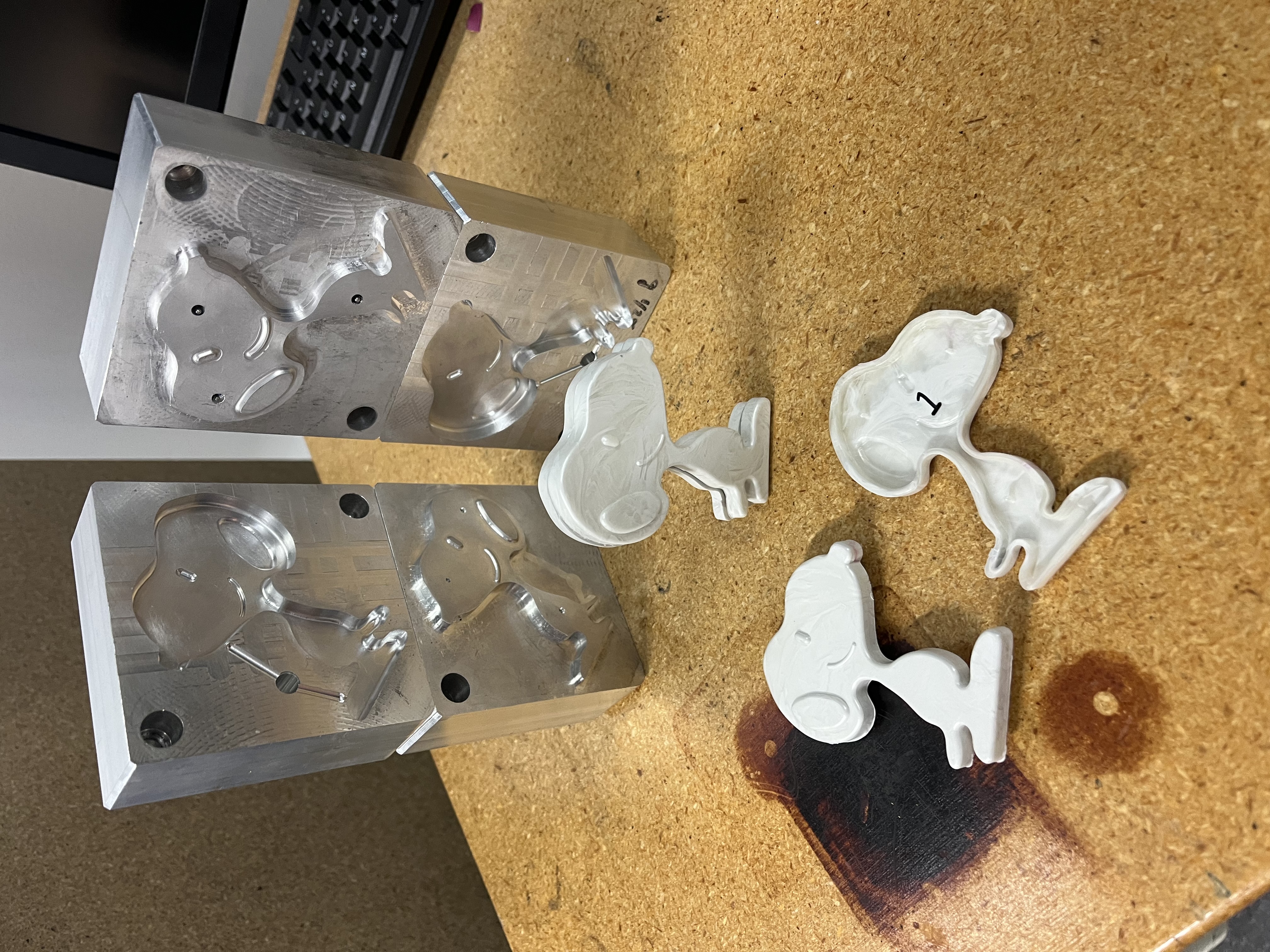

Injection Molded Snoopy

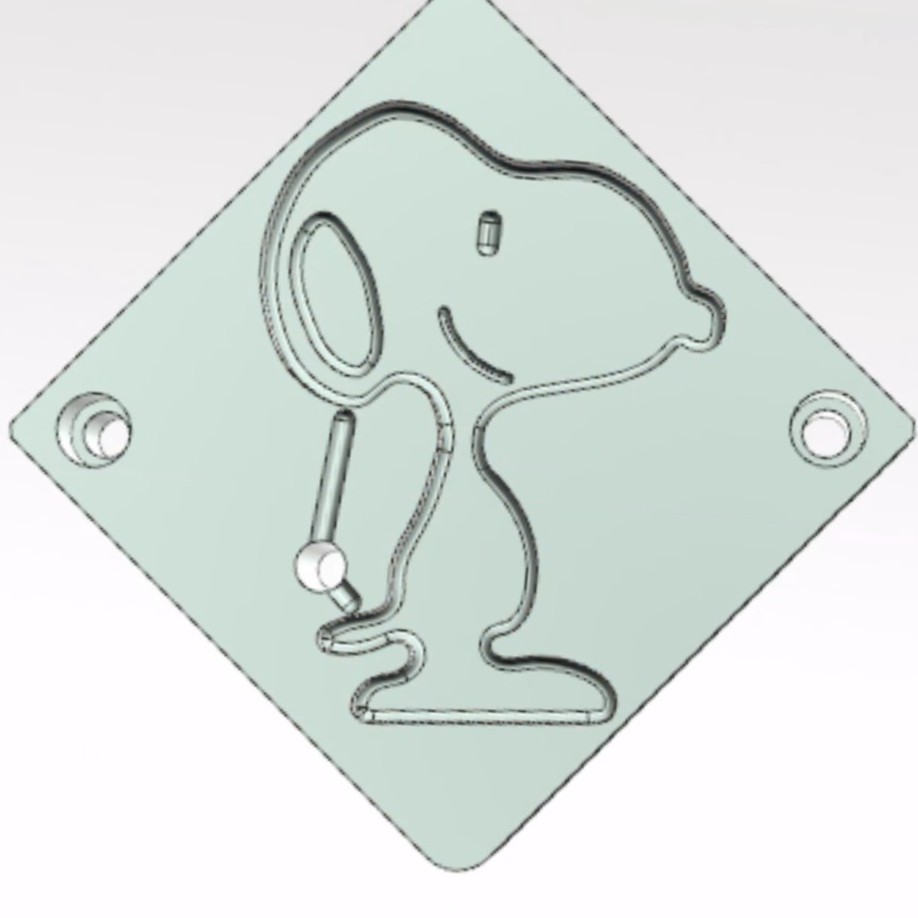

For an advanced manufacturing class, I worked on a team designed and produced an injection-molded Snoopy figure. The project involved CAD/CAM design, machining, and injection molding two thin-walled halves that assemble using pin and socket interference fits. I had to incorporate key manufacturing considerations to ensure the final product was not only aesthetically pleasing but also functional and durable. Siemens NX was used for the CAD design, ensuring precise dimensions and fit. The final product is a testament to my understanding of manufacturing processes and my attention to detail. Click here to see the full write-up of the project.