Swift Latch

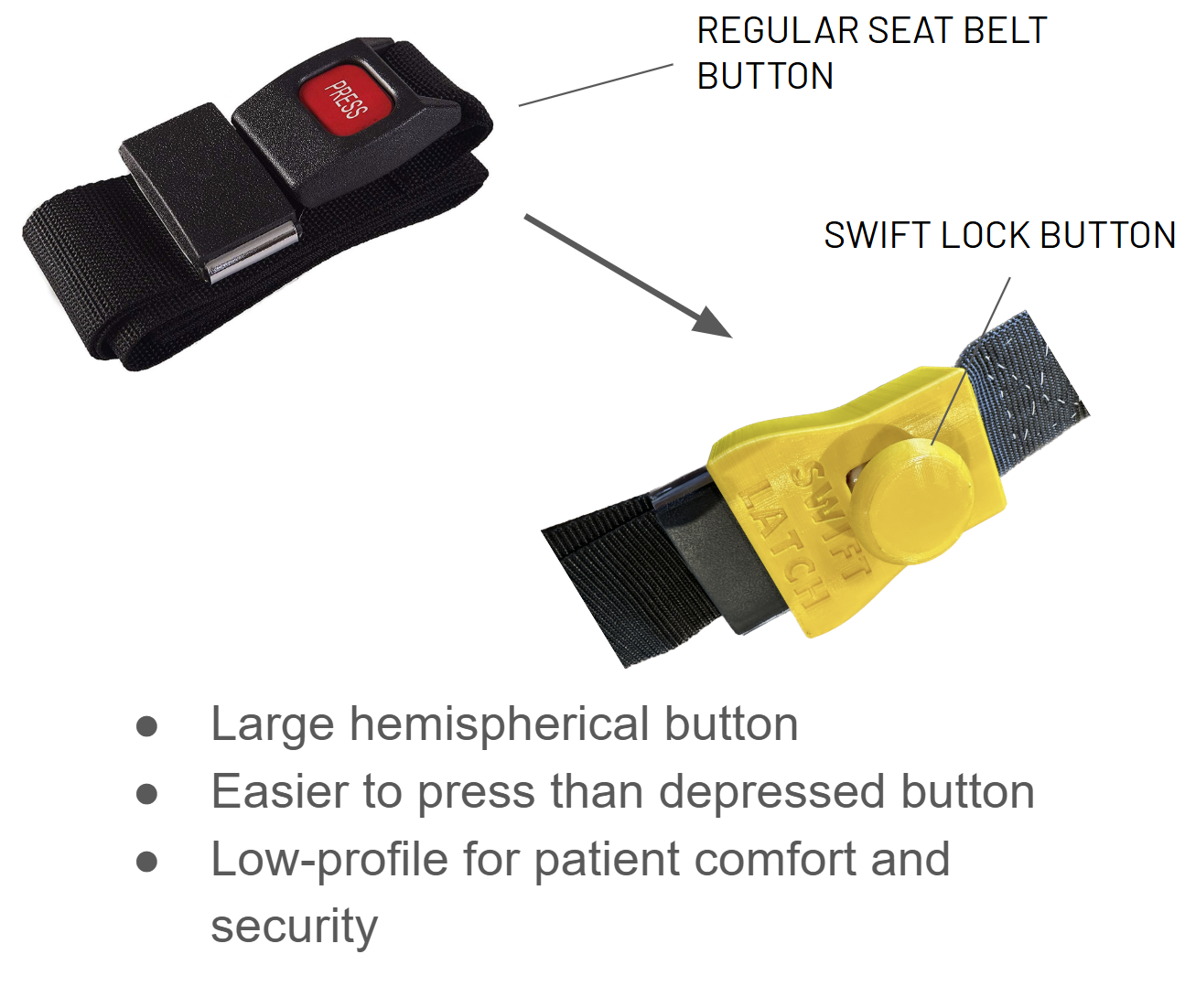

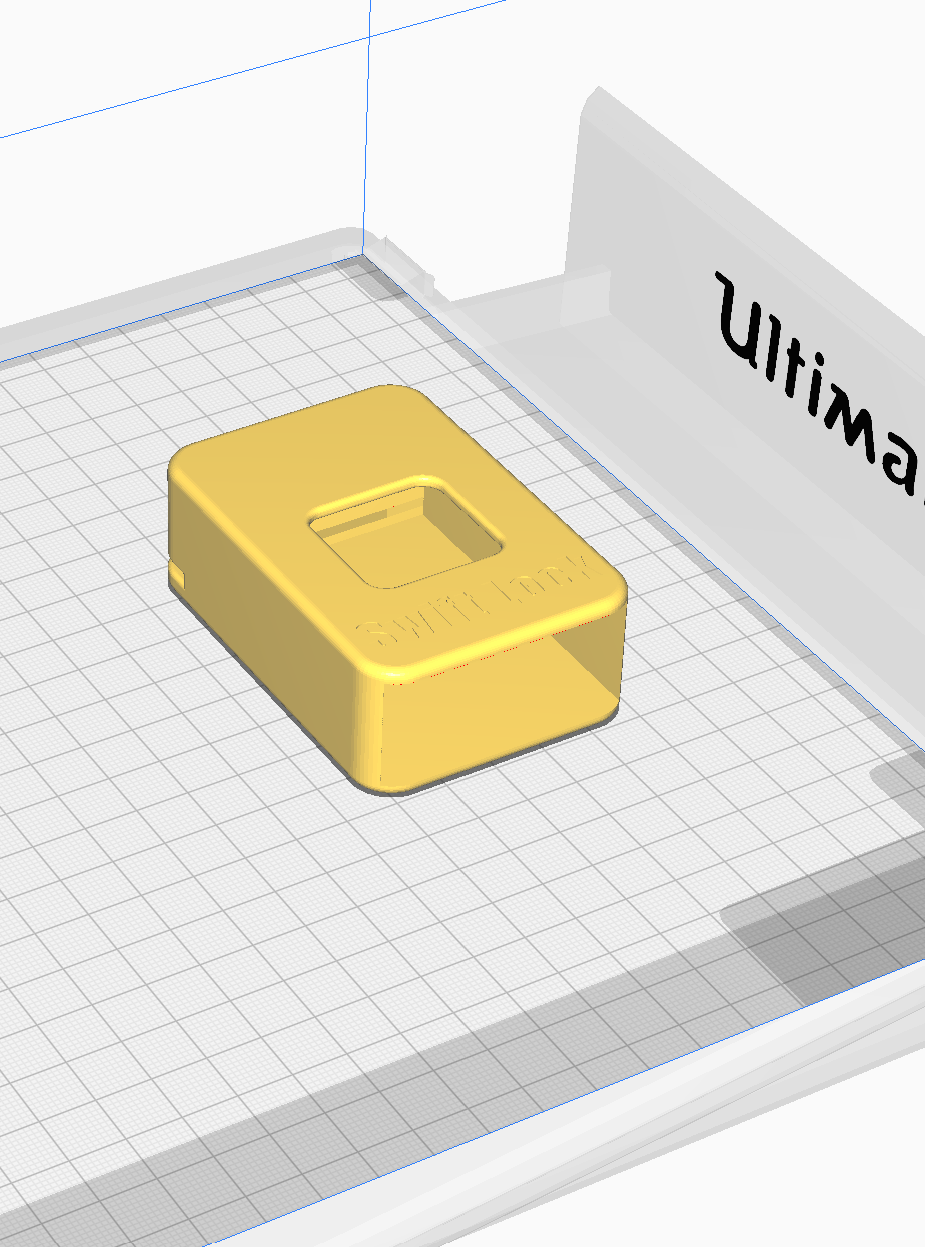

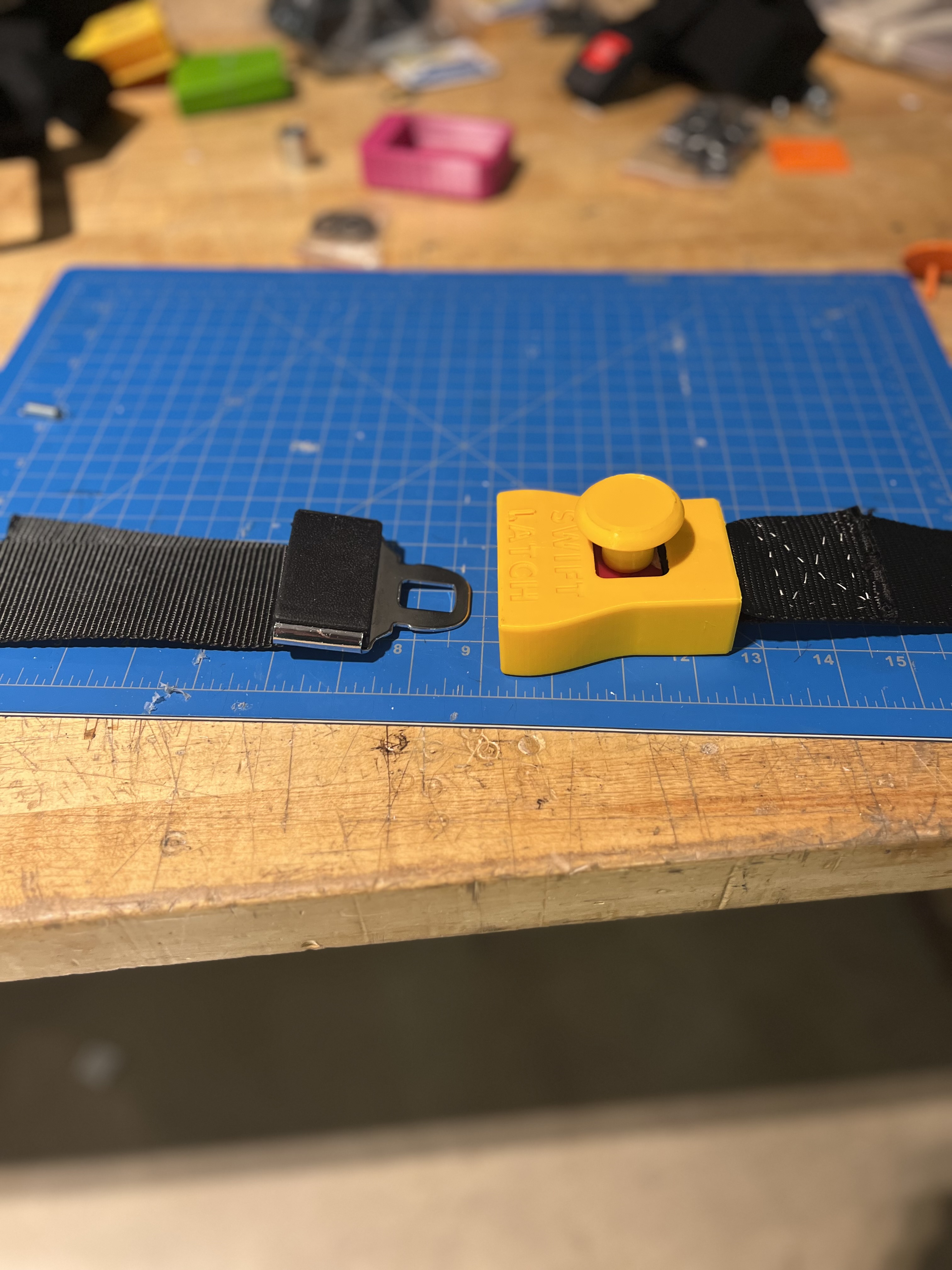

For a class project, we worked to address a challenge faced by wheelchair users at Alexian Brothers Rehabilitation Hospital (ABRH), who require seat belts for safety but struggle with the current hook-and-loop straps due to cleaning and security issues. The design had to meet ABRH’s no-restraint restrictions, ensuring patients could latch and unlatch the seat belt independently, while also being easy to clean with wet wipes. After testing mockups with wheelchair users and incorporating feedback, we developed the Swift Latch, featuring a large press button and a tapered shell for easy operation by patients with limited motor control. Made from materials compatible with ABRH’s cleaning guidelines, the Swift Latch also includes adjustable webbing and carabiners to fit various wheelchair sizes. This solution balances patient safety, independence, and caregiver convenience.